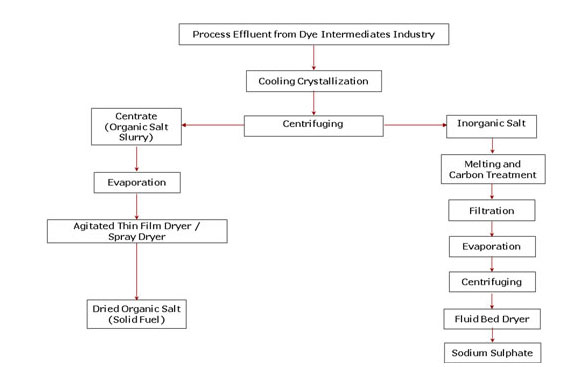

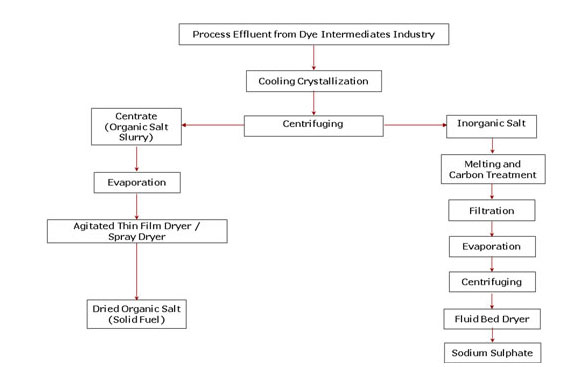

The effluent from the dye/dye intermediate industries containing a mix of organic and inorganic salts is treated using Evaporation and Drying Technology to separate the organic and inorganic salts. The organic salts are used as a solid fuel and the inorganic salt can be a marketable product.The scheme shown above depicts that the effluent is crystallized at first and after centrifuging, the concentrate from the centrifuge comprising organic salts is concentrated using evaporator and then the concentrate is dried using the Agitated Thin Film Dryer or Spray Dryer.

The effluent from the dye/dye intermediate industries containing a mix of organic and inorganic salts is treated using Evaporation and Drying Technology to separate the organic and inorganic salts. The organic salts are used as a solid fuel and the inorganic salt can be a marketable product.The scheme shown above depicts that the effluent is crystallized at first and after centrifuging, the concentrate from the centrifuge comprising organic salts is concentrated using evaporator and then the concentrate is dried using the Agitated Thin Film Dryer or Spray Dryer.

On the other hand, the inorganic salts obtained after centrifuging are melted and treated with Activated Carbon. After separation of carbon from the slurry, the resulting slurry is concentrated using an Evaporator. The concentrate from this evaporator is passed through Centrifuge to obtain inorganic salts with high purity. The salt obtained from the centrifuge now can be dried using a Fluidized Bed Dryer.

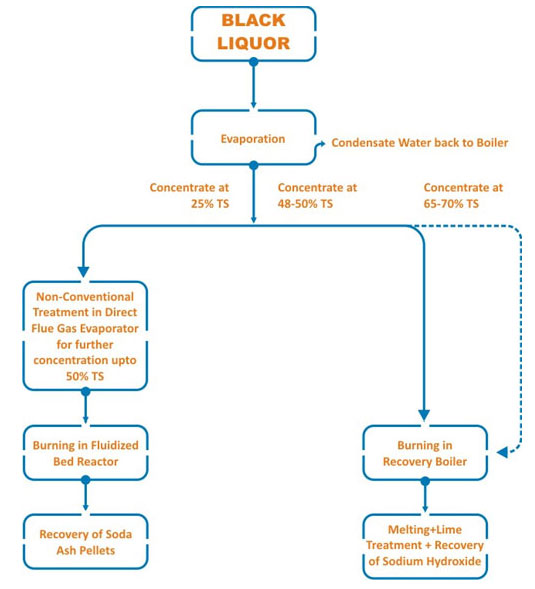

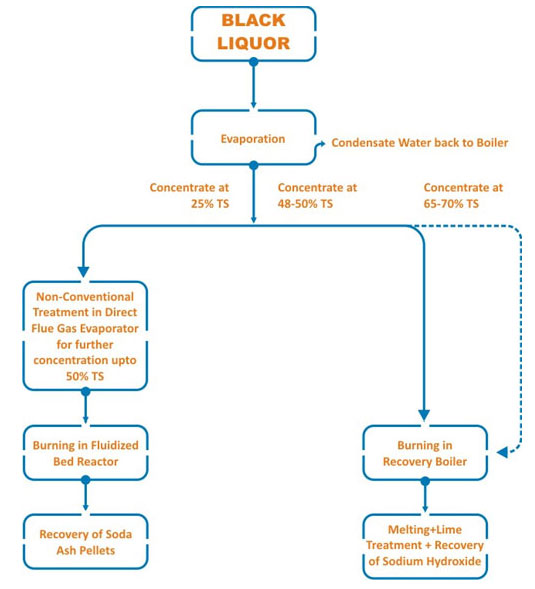

In pulp mills spent liquor produced during washing of pulp after cooking with Caustic is highly toxic and this cannot be discharged. So its treatment in recovery plant is must. Valuable inorganic chemicals recovery is also done to keep pulping cost under control.

In pulp mills spent liquor produced during washing of pulp after cooking with Caustic is highly toxic and this cannot be discharged. So its treatment in recovery plant is must. Valuable inorganic chemicals recovery is also done to keep pulping cost under control.

Recovering inorganic chemicals is possible only by incineration of black liquor but since the liquor is in very dilute form containing as low as 8 to 10% solids, it is not economical to incinerate directly. For burning this liquor, it is evaporated in Multiple Effect Evaporator to the desired concentration i.e. 48% in case of conventional recovery or 25 % in case of non conventional systems and then subsequently incinerated.

In case of conventional method of recovery, inorganic chemicals are collected in molten form named smelt. The smelt when dissolved in hot water becomes green liquor which is nothing but maximum sodium carbonate. This Green Liquor is further treated with lime to produce sodium hydroxide which is reused in pulp mill for pulping fibrous raw materials.

In case of non-conventional method of recovery, liquor at 25% TS is further concentrated to 50 % in direct contact flue gas evaporator and burnt in fluidized bed reactor in which inorganic chemicals are recovered at pre-melting stage in the form of soda ash pellets which are sold in the market.

This is how pollution abatement and inorganic chemical recovery is achieved in pulp and paper industries.

KEY FEATURES:

- Zero Liquid Discharge System.

- Produce Black Liquor Concentrate.

- Highly Energy Efficient (Evaporates 7 Kg of water / kg of steam for concentration upto 50% in Seven Effect Evaporator).

- Minimum Space requirement.

- Fully Customized Design System.

- Low Operating Cost.

- Less Downtime for Maintenance.

- Operator friendly.

Dye / Dye Intermediates Industries

Dye / Dye Intermediates Industries The effluent from the dye/dye intermediate industries containing a mix of organic and inorganic salts is treated using Evaporation and Drying Technology to separate the organic and inorganic salts. The organic salts are used as a solid fuel and the inorganic salt can be a marketable product.The scheme shown above depicts that the effluent is crystallized at first and after centrifuging, the concentrate from the centrifuge comprising organic salts is concentrated using evaporator and then the concentrate is dried using the Agitated Thin Film Dryer or Spray Dryer.

The effluent from the dye/dye intermediate industries containing a mix of organic and inorganic salts is treated using Evaporation and Drying Technology to separate the organic and inorganic salts. The organic salts are used as a solid fuel and the inorganic salt can be a marketable product.The scheme shown above depicts that the effluent is crystallized at first and after centrifuging, the concentrate from the centrifuge comprising organic salts is concentrated using evaporator and then the concentrate is dried using the Agitated Thin Film Dryer or Spray Dryer.

In pulp mills spent liquor produced during washing of pulp after cooking with Caustic is highly toxic and this cannot be discharged. So its treatment in recovery plant is must. Valuable inorganic chemicals recovery is also done to keep pulping cost under control.

In pulp mills spent liquor produced during washing of pulp after cooking with Caustic is highly toxic and this cannot be discharged. So its treatment in recovery plant is must. Valuable inorganic chemicals recovery is also done to keep pulping cost under control.